Two types of data, two complementary perspectives

In a Travaglini system, not all data are the same.

- Sensors detect and monitor the operating conditions of the system: technical parameters, flow stability, overall efficiency.

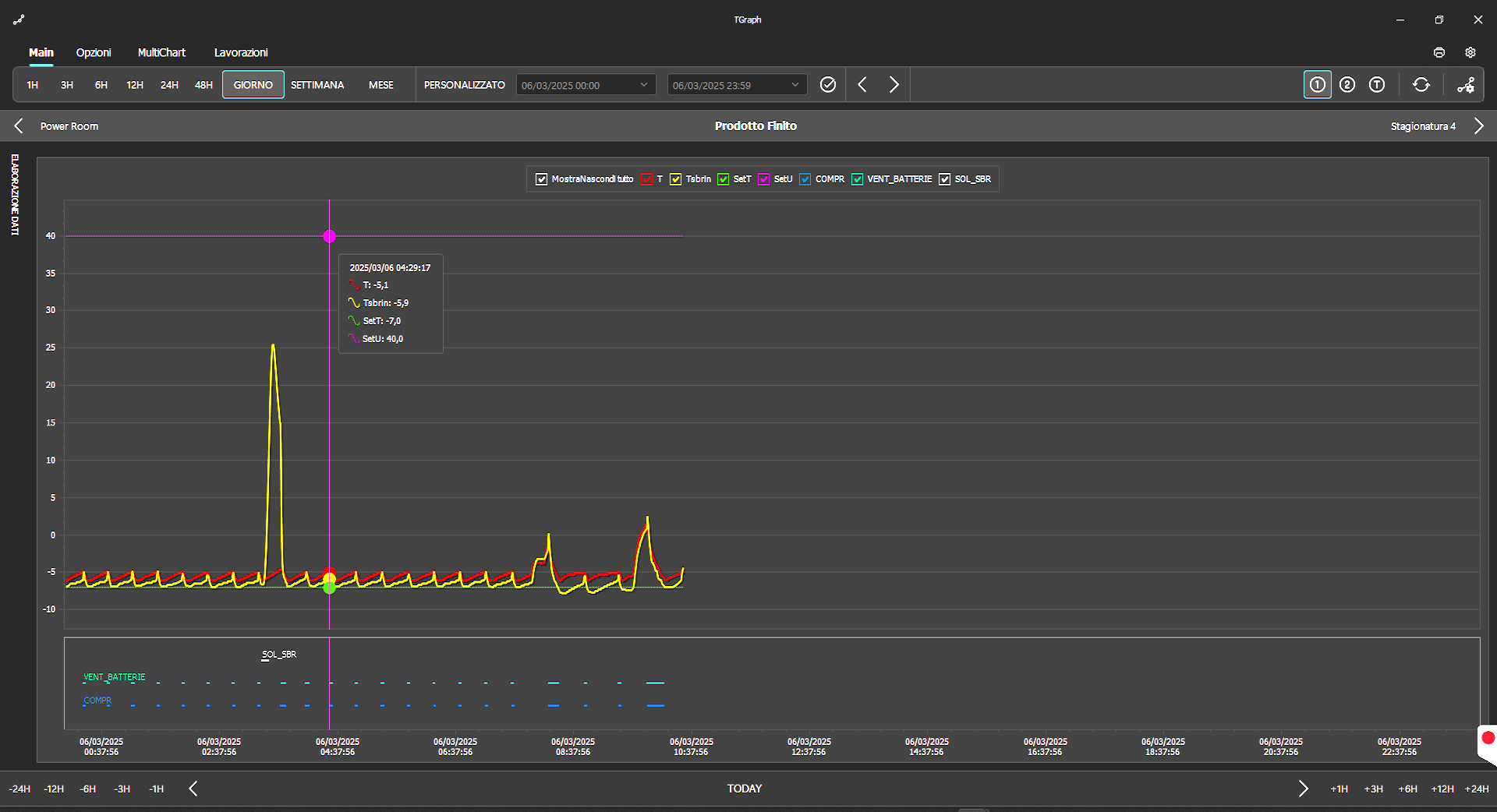

- Probes measure the product’s response during the different phases of the process, describing its evolution in real time.

These are two different perspectives — Technique and Technology — that together provide a complete view of the production process.

From raw data to useful information

Collecting data is only the first step.

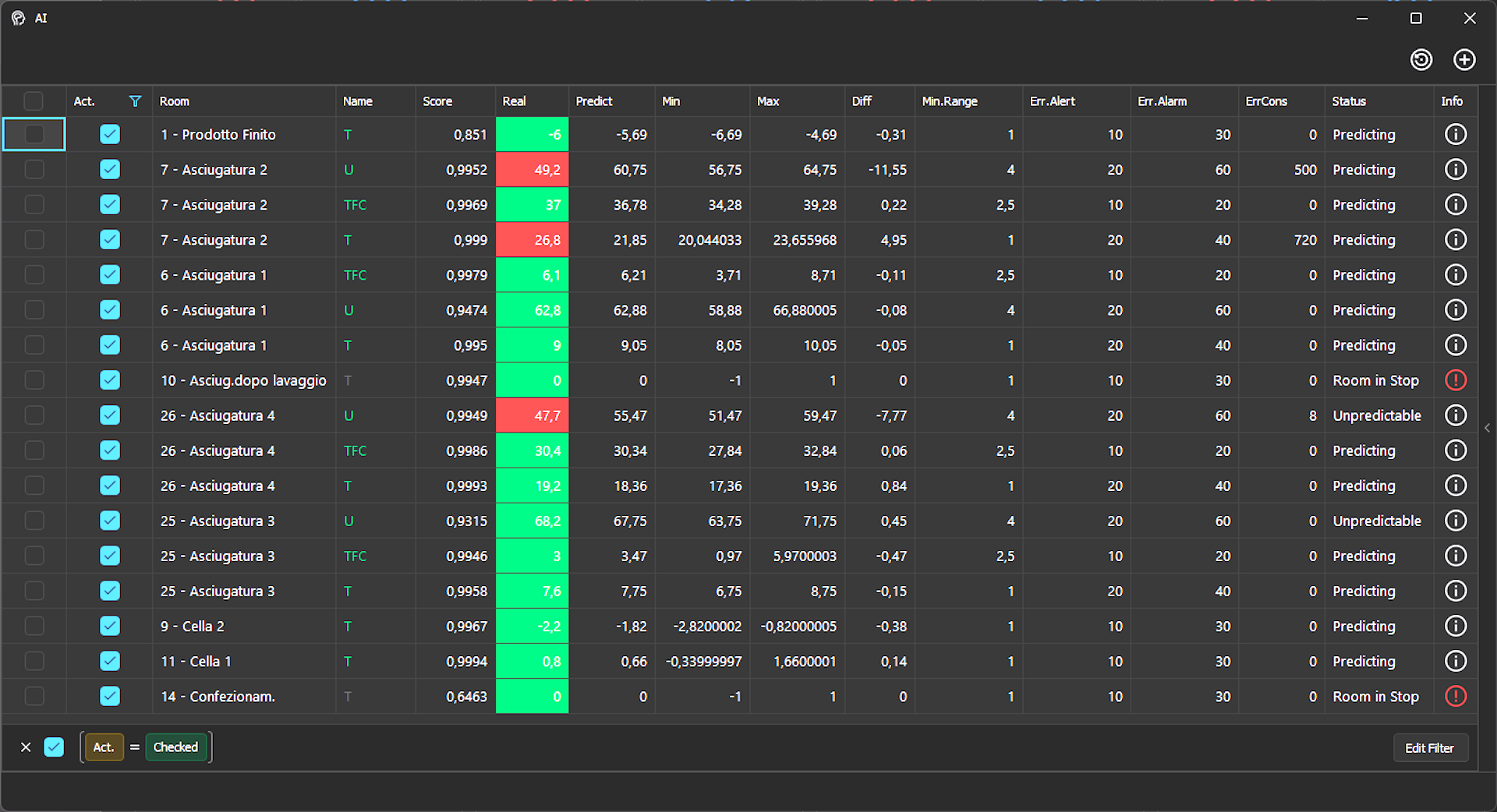

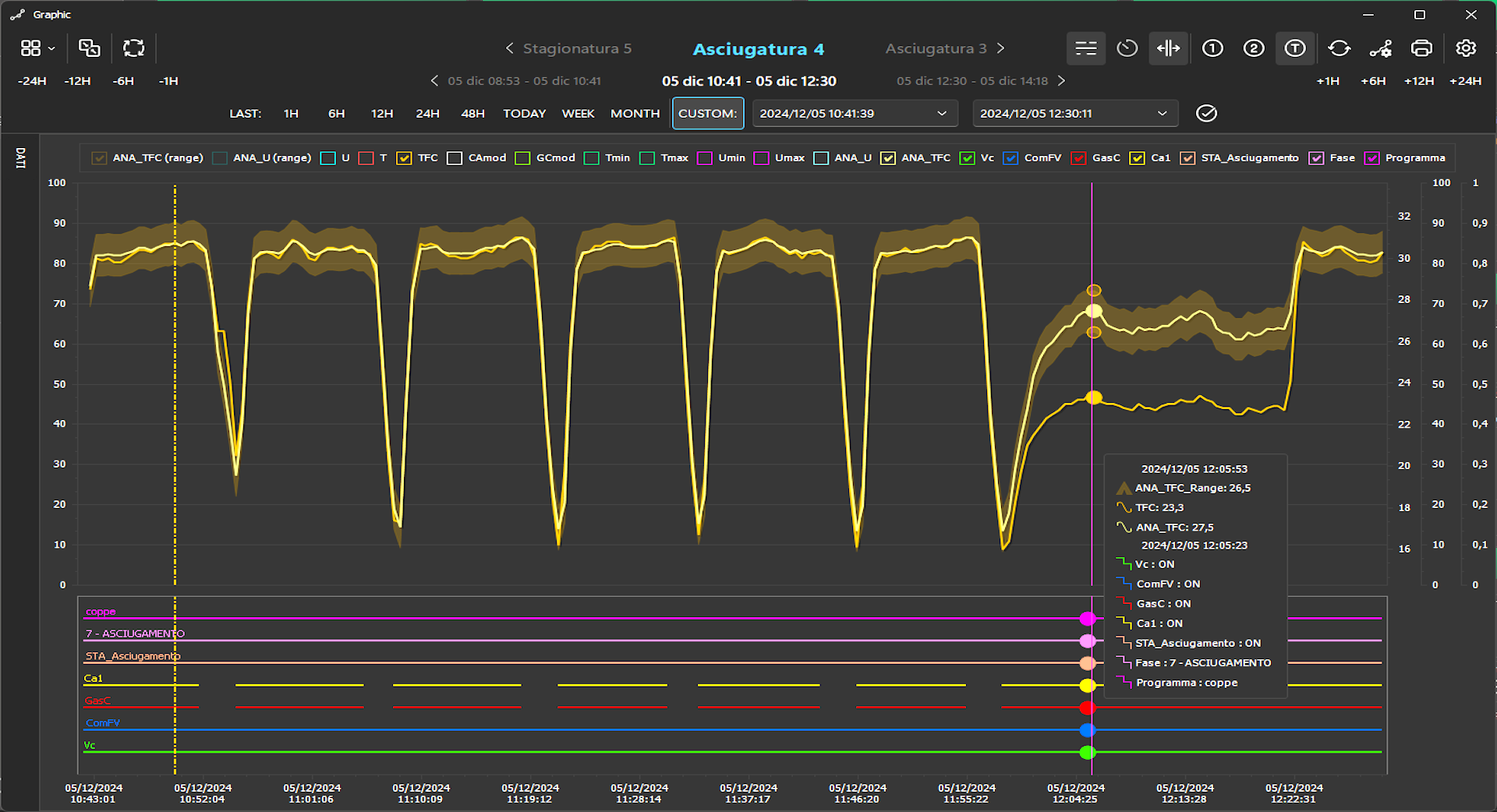

Through our control units and our dedicated software, sensors and probes communicate within a single system. The recorded values are processed, correlated, and placed on a timeline.

In this way, raw data are transformed into useful information:

- making it possible to analyze the process at every single stage,

- identifying deviations or anomalies before they become issues,

- adjusting parameters in real time to maintain full control.

Safety, consistency and constant quality

The #DataDriven approach does more than improve efficiency: it guarantees safety and quality. Managing the process through accurate, timely data means reducing risks, optimizing timing, and ensuring that every batch complies with customer specifications.

For Travaglini, this translates into a concrete result: producing exactly what the customer requires, in the right quantity and with the expected quality, day after day.

Conclusion

The combination of sensors, probes, control units and software represents a unique ecosystem. This is where Technique meets Technology, and where data are transformed into real value for the customer.